Aktualności

Pozostałe

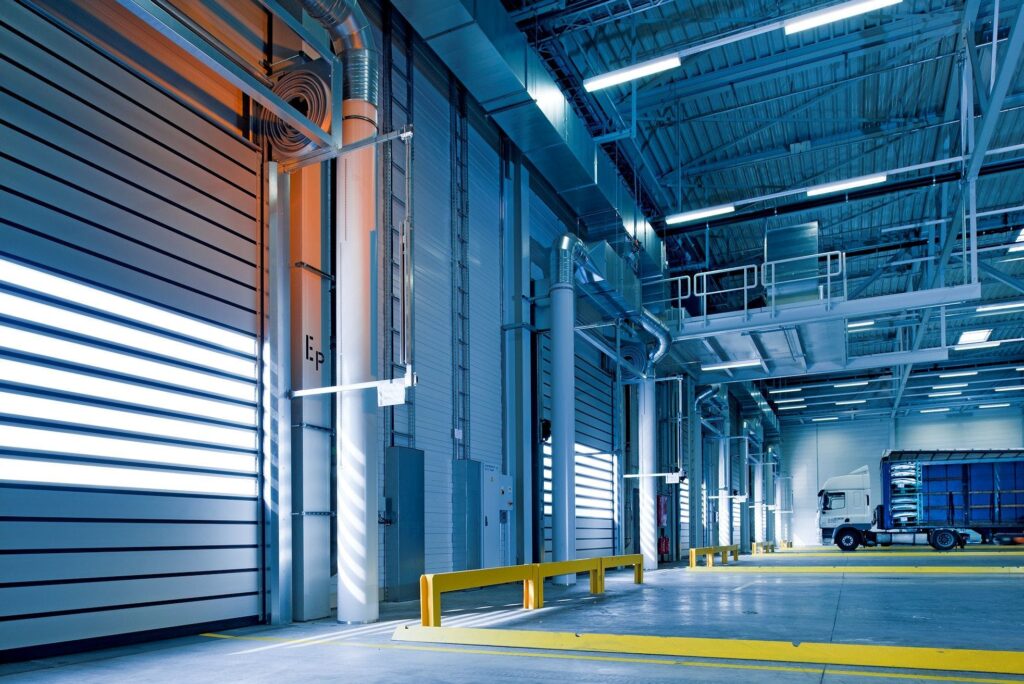

W dzisiejszym dynamicznym środowisku przemysłowym relokacja maszyn odgrywa kluczową rolę w utrzymaniu konkurencyjności i efektywności…

Czytaj dalej

Przemysł to niezwykle ważny dział gospodarki, który zajmuje się produkowaniem różnych dóbr. Praca firm przemysłowych…

Czytaj dalej

Energia pozyskiwana z wiatru może być sposobem na zaopatrzenie domu lub większego gospodarstwa w energię…

Czytaj dalej

Każdy z nas ma wpływ na stan Ziemi, decyzje podejmowane przez pojedyncze osoby dają razem…

Czytaj dalej

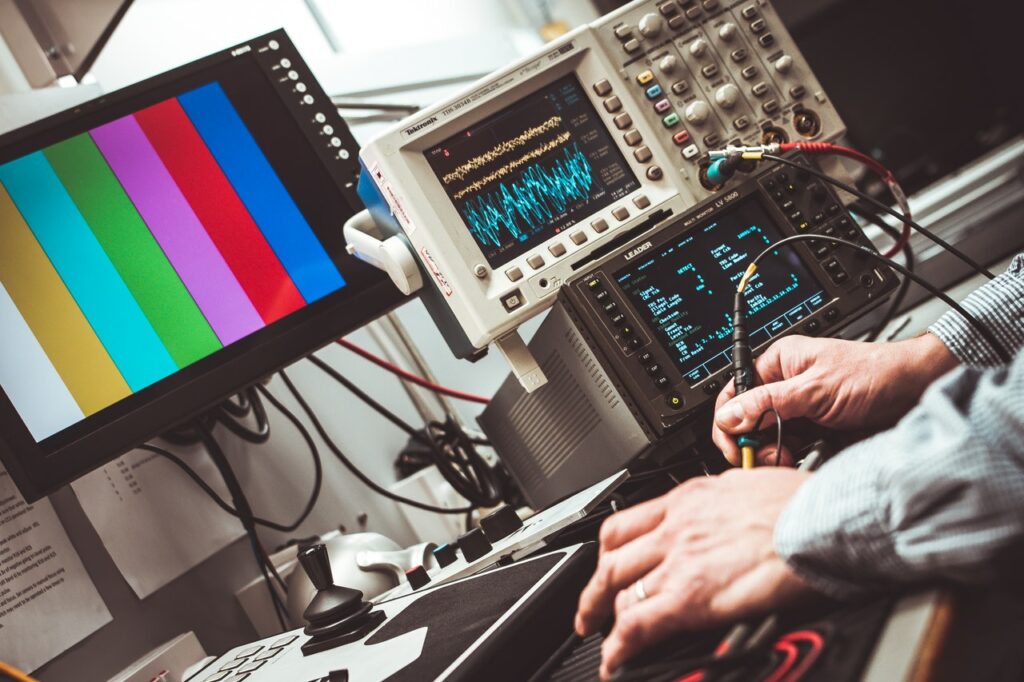

Może być przemysł samochodowy, włókienniczy, odzieżowy czy IT. Każdy z nich korzysta z nowoczesnych urządzeń.…

Czytaj dalej

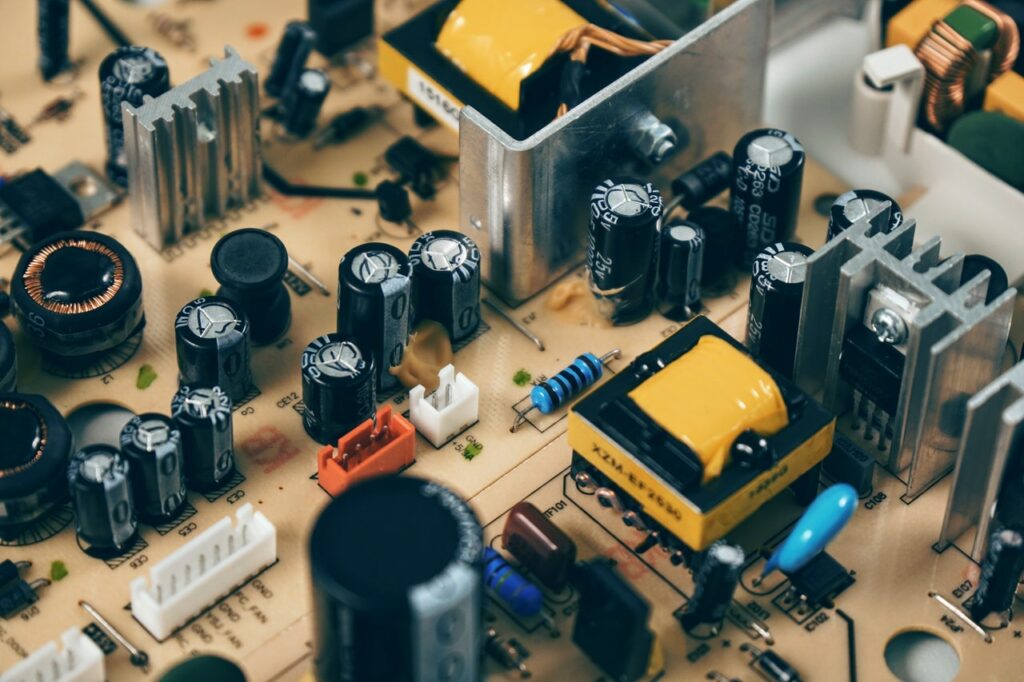

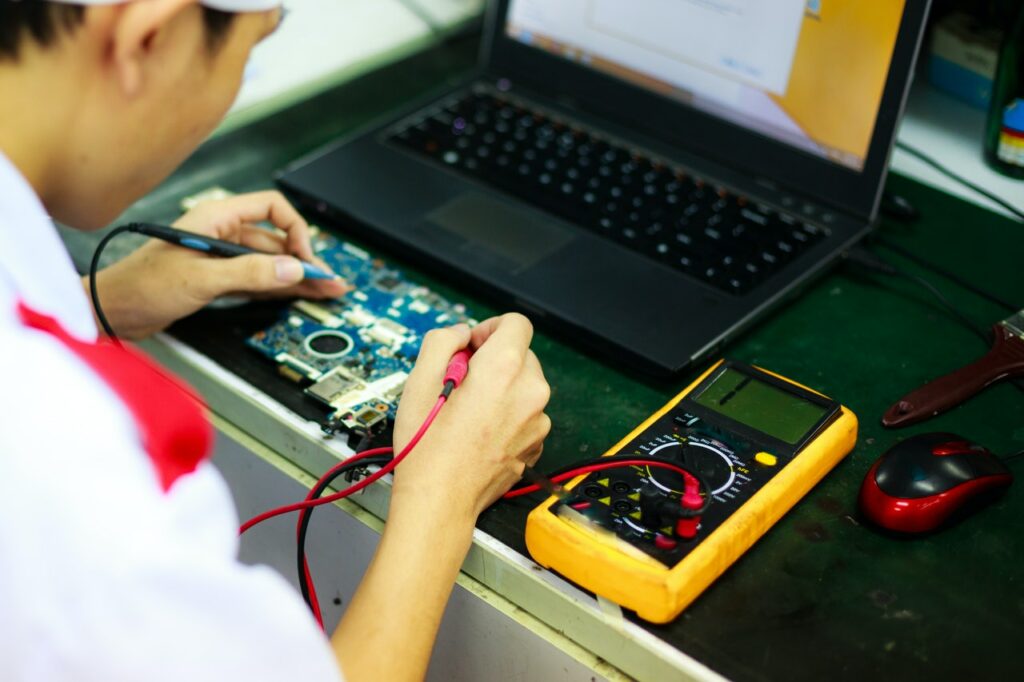

Sprzęty elektroniczne w naszym codziennym życiu ułatwiają nam bardzo często wiele różnych rzeczy, dlatego też…

Czytaj dalej

Budując dom, zwykle nabywamy wiedzy z wielu dziedzin o których do tej pory nie mieliśmy…

Czytaj dalej

Wykorzystanie energii z urządzeń pneumatycznych jest mniej popularne, gdyż takie urządzenia wypierane są przede wszystkim…

Czytaj dalej

Nie da się zaprzeczyć, że sytuacja, w której ceny paliw systematycznie rosną doprowadza do tego,…

Czytaj dalej

Osoby które zajmują się instalacją sieci gazowych, wodociągowych czy kanalizacyjnych, mających zastosowanie w domu czy…

Czytaj dalej